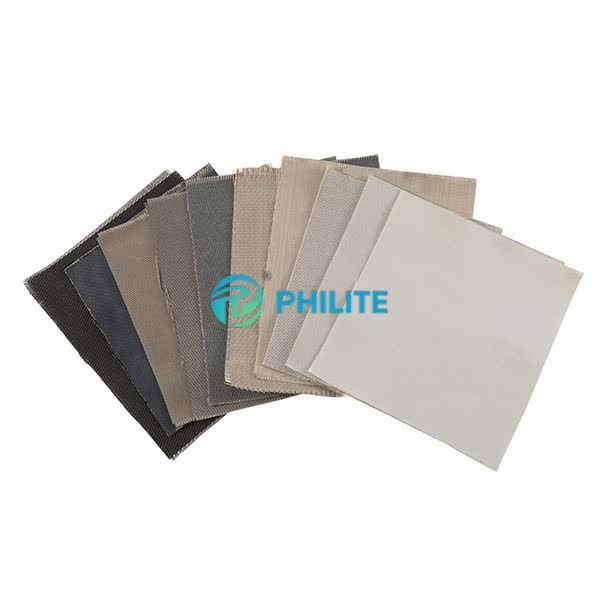

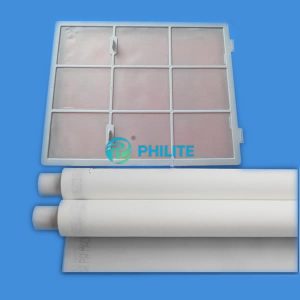

Fiberglass filter cloth is a material commonly used to filter and separate solid particles in industrial processes. It is made of fiberglass and has excellent chemical stability, high temperature resistance, corrosion resistance and mechanical strength. This makes fiberglass filter cloth widely used in many industries, such as chemical industry, petroleum, pharmaceutical, water treatment, metal processing, etc.

- Thickness: 0.30~0.83mm.

- Air permeability: Can be customized.

- Operating temperature: 260℃

- Instant temperature: 280℃

- Available weight: 350, 380, 450, 550, 750, 800 gsm.

- Weave: plain, twill, satin.

- Capacity: 2000 m² per day.

Description

Characteristics of Fiberglass Filter Cloth

- High temperature resistance.

- Dust peels off easily.

- Good dimensional stability and almost zero shrinkage.

- It has good chemical resistance and is stable to other media except hydrofluoric acid, strong acid and strong alkali.

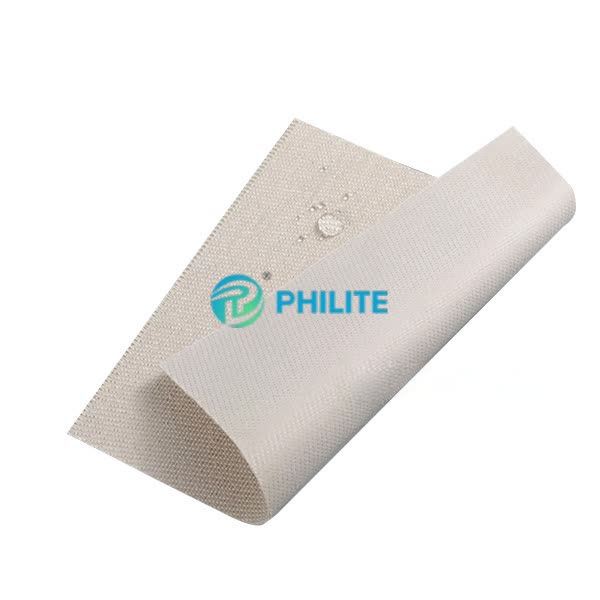

- Does not absorb water or moisture.

Our Advantages

- High-quality fiberglass yarn: Our selected 6μm fiberglass yarn with high strength, high stiffness and corrosion resistance.

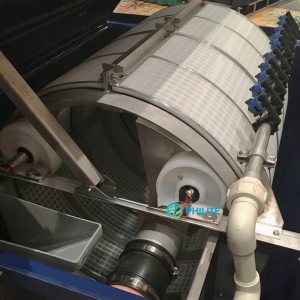

- Advanced production equipments: Filmedia is equipped with advanced jet looms, rapier looms and warping machines to ensure the stable and high qualified media We produce.

- Strict quality inspection: Finally, the processed fiberglass filter cloth will undergo quality inspection. This includes inspecting the appearance, size, strength, filtration performance, etc. of the fabric to ensure it meets design requirements and application standards.

Finish Treatments

We independently designed and developed special equipment for desizing and PTFE impregnation ensuring efficiency and reducing the unqualified rate of the two processes:

- PTFE membrane: Our laminating machine uses imported high temperature heating roller. The roller surface temperature tolerance is ±1 ℃ ensuring the film fastness and uniformity. PTFE membrane thickness is 15um. The max membrane width can be 2.2M.

- PTFE impregnation, PTFE membrane, Anti Acid, Silicon+Graphite+PTFE treatment.

Performance Parameters

| Product code | FM-FB380WM | ES-FB480W-PSG | ES-FB520W-AR | ES-FB800W-TFM | |

| Physical properties | |||||

| Weave method | 1/3 Twill | 1/3 Twill | 1/3 Twill | Double Twill | |

| Thickness | 0.5+0.08 | 0.50+0.08 | 0.55+0.08 | 0.80+0.08 | |

| Weight (g/m) | 380+15 | 480+10 | 520+10 | 800+10 | |

| Loss on Ignition (%) | >10 | 210 | 210 | 210 | |

| Chemical Finish | PTFE impregnation, PTFE membrane, silione and graphite treatment | Teflon, Silicon, Graphite finish | Acid resistant finish | Teflon, PTFE membrane finish | |

| Air Permeability _(L/m2S@200Pa) | 20-50 | 350+25 | 340+25 | 60₁15 | |

| Density (ROOT/INCH) | warp | 54+2 | 48+2 | 48+2 | 48+2 |

| weft | 30+2 | 25+2 | 25+2 | 42+2 | |

| Tensile Strength (N/25mm) | Warp | >1200 | >2000 | 48+2 | >2400 |

| Weft | >1000 | 21200 | 25+2 | 2200 | |

| Temperature | |||||

| Continues temperature(°C) | 250 | 250 | 250 | 250 | |

| Instant temperature(°C) | 280 | 280 | 280 | 280 | |

Applications of Fiberglass Filter Cloth

Philite® fiberglass filter cloth can be used for industrial dust collection. Fiberglass woven cloth bag is widely used in industry of Cement, Black carbon, Iron & Steel, Iron alloy, Thermal power, Coal-fired furnace and so on.

Related products

-

Woven Filter Cloth

Drum Filter Cloth

-

Liquid Filter Bags

Polypropylene Filter Bags

-

Filter Paper

Glass Microfiber Filter Paper

-

Filter Mesh

Filter Mesh in Flour Mill

Search Products

Product Category

- Uncategorized

- Air Filters

- Air Slide Fabric

- Bag House Filters

- Filter Bag Accessories

- Filter Bag Making Machine

- Filter Cartridges

- Filter Elements

- Filter Fibers

- Filter Housing

- Filter Mesh

- Filter Paper

- Filter Systems

- Honeycomb Catalyst Filter Device

- Industrial Filter Bags

- Industrial Filter Cloth

- Paper Filter

- PTFE Accessories Products

- Reverse Osmosis Membrane

- Sewing Threads

- Sintered Metals

- Spare parts of Dust collector

- Wastewater Treatment Machinery