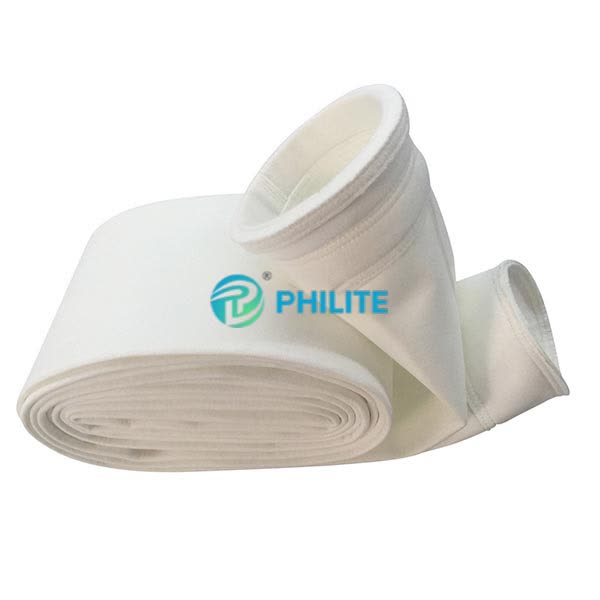

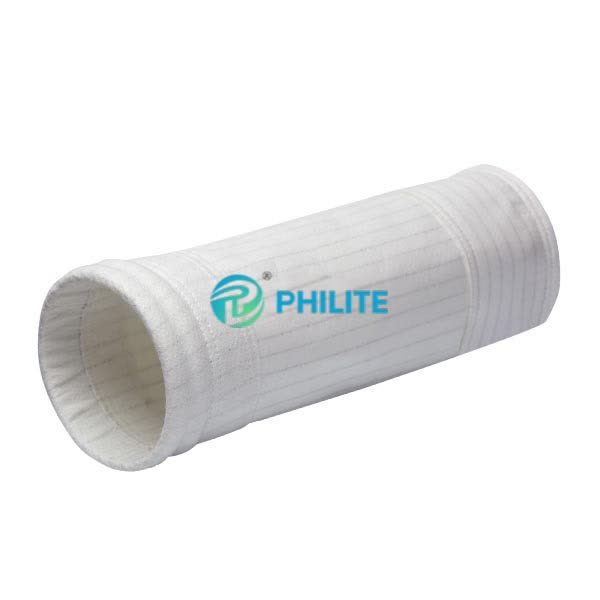

Industrial water filter bags are essential for removing particulates from liquids in various processes. They are typically designed for high flow rates and can handle large volumes of water. Philite ® water filter bags offer economical filtration for a wide array of applications. Highly controlled manufacturing procedures ensure consistent quality and no contamination. The unique bag designs provide added strength and avoid risk of bypass. Our filter bags fit all industry-standard bag housings.

- Available medias range from 1-1000 µ.

- Wide array of silicone-free media fibers.

- Meeting needed temperature and micron specifications.

- Bag finish or covers available for strict migration requirements.

- Customized and specialty bags available.

Category Liquid Filter Bags

Tag Wet Filtration

Description

Optional Size for Water Filter Bags (Micron Rating)

| Grade | Level 1(μm) | Level 2 (μm) | Level 3 (μm) | Level 4 (μm) | ||||||||||||

| Pore size | 1.5 | 10 | 25 | 50 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 800 |

4 Standard Products (We also accept customization of size)

| Model | Filter area (m2/ pcs) | Volume (L) | Diameter | Length | ||

| cm | inch | cm | inch | |||

| Type 1 | 0.19 | 7.9 | 17.8 | 7 | 40.65 | 16 |

| Type 2 | 0.41 | 17.3 | 17.8 | 7 | 81.3 | 32 |

| Type 3 | 0.05 | 1.4 | 10.2 | 4 | 20.9 | 8.25 |

| Type 4 | 0.09 | 2.5 | 10.2 | 4 | 35.5 | 14 |

Different Filter Fabrics for Water Filter Bags

There are two main materials commonly used for water filter bags, one is needle felt material (Polypropylene, Polyester, PTFE), and the other typical material is mesh material (nylon).

| Material | Chemical Resistance | Temperature Resistance | Durability |

| Polypropylene | Good (most chemicals) | Up to 82°C (180°F) | Moderate |

| Polyester | Fair (some solvents) | Up to 100C (212°F) | High |

| Nylon | Excellent (most chemicals) | Up to 120C (248°F) | High |

| PTFE(Teflon) | Excellent (most chemicals) | Up to 260°℃ (500°F) | Very High |

Applications

- Industrial Filtration: Used in manufacturing processes to filter out particulates and contaminants from liquids, ensuring product quality in industries like food and beverage, pharmaceuticals, and chemicals.

- Wastewater Treatment: Employed in municipal and industrial wastewater treatment facilities to remove suspended solids and other pollutants before discharge.

- Aquaculture: Utilized in fish farming to maintain water quality by filtering out waste and uneaten feed.

- Swimming Pools: Used in pool filtration systems to capture debris and maintain clear water.

- Beverage Filtration: Common in the brewing and winemaking processes to clarify liquids by removing solids.

- Water Purification: In residential settings, filter bags are used in systems that treat drinking water, improving safety and taste.

- Pharmaceuticals: Applied in the production of medicines to ensure that liquids are free from contaminants.

- Oil and Gas: Employed in separation processes to filter out particulates from drilling fluids and other liquids.

Related products

-

Woven Filter Cloth

Disc Filter Cloth

-

Liquid Filter Bags

Polyester Filter Bags

-

Liquid Filter Bags

Stainless Steel Filter Bags

-

Filter Mesh

Industry Mesh

Search Products

Product Category

- Uncategorized

- Air Filters

- Air Slide Fabric

- Bag House Filters

- Filter Bag Accessories

- Filter Bag Making Machine

- Filter Cartridges

- Filter Elements

- Filter Fibers

- Filter Housing

- Filter Mesh

- Filter Paper

- Filter Systems

- Honeycomb Catalyst Filter Device

- Industrial Filter Bags

- Industrial Filter Cloth

- Paper Filter

- PTFE Accessories Products

- Reverse Osmosis Membrane

- Sewing Threads

- Sintered Metals

- Spare parts of Dust collector

- Wastewater Treatment Machinery