Description

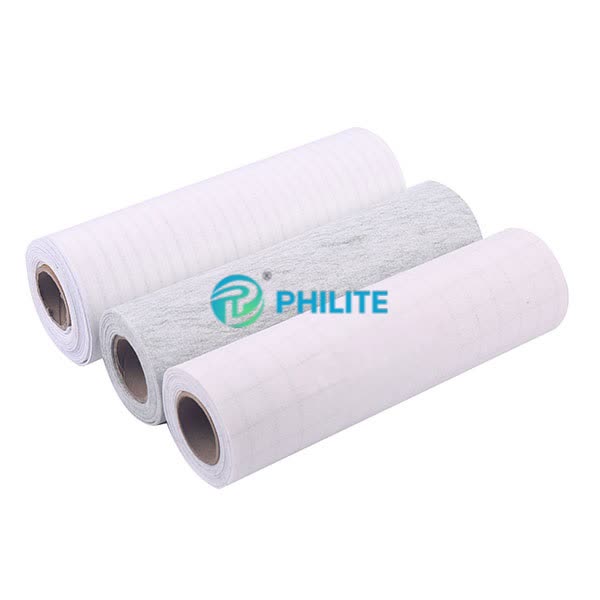

Anti-static needle PE/Polyester punched felt is one of the most common materials used to make filter bags, which always used in environments prone to dust explosions. There are mainly 2 types: line type, cross type and blend/mixed type.

PE/Polyester Properties

| Material | Working Temperature | Instant Temperature | Abrasion Resistance | Hydrolysis Resistance | Acid Resistance | Alkali Resistance | Oxidation Resistance |

| PE/Polyester Needle Felt | 130℃ | 150℃ | Excellent | Middle | Middle | Middle | Good |

Post-treatment

For Anti-static needle PE/Polyester needle punched felt, we can treat it with different post-processing according to different working conditions. There are mainly the following post-processing treatments:

- Water&OilRepellent

- PTFE Membrane

- PTFE Impregnation

Shapes and Types

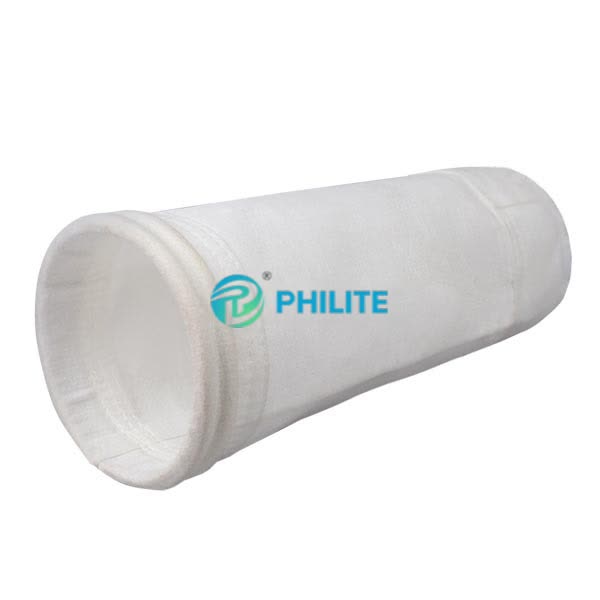

Anti-static needle PE/Polyester needle felt can be made into different types of filter bags, which can be mainly divided into the following three types according to different shapes:

- Roundtype

- Flat type

- Star/pleated type

Application

Filter bags made of Anti-static needle PE/Polyester needle punched felt are widely used in many industries:

- Cement Plant

- Lime Stone

- Iron&Steel Plant…

Related products

-

Needle Punched Felt

FMS Needle Felt Filter Cloth

-

Dust Filter Bags

PTFE Filter Bags

-

Air Slide Fabric

Airslide Canvas

-

Needle Punched Felt

Acrylic Needle Felt Filter Cloth

Search Products

Product Category

- Uncategorized

- Air Filters

- Air Slide Fabric

- Bag House Filters

- Filter Bag Accessories

- Filter Bag Making Machine

- Filter Cartridges

- Filter Elements

- Filter Fibers

- Filter Housing

- Filter Mesh

- Filter Paper

- Filter Systems

- Honeycomb Catalyst Filter Device

- Industrial Filter Bags

- Industrial Filter Cloth

- Paper Filter

- PTFE Accessories Products

- Reverse Osmosis Membrane

- Sewing Threads

- Sintered Metals

- Spare parts of Dust collector

- Wastewater Treatment Machinery